Bending, cutting, welding

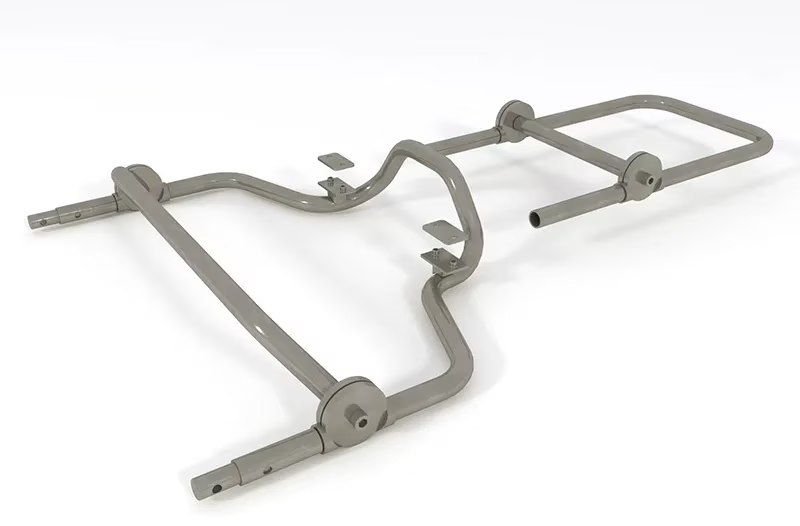

We have modern tube processing machines in our factory in Nijverdal. We use them to process round, square and flat-oval tubes. For extremely precise bending work we use a mandrel bending machine. For the production of arc-shaped tubes we work with advanced, CNC-controlled profile rollers. We cut your tubes with laser cutters. Thanks to the computer control, almost any design can be realized.

We produce your composite tube and/or wire constructions using spot welding (resistance welding) and, if necessary, Mig/Mag or Tig welding.

From prototype to mass production

Would you like to thoroughly examine and test your tube model before having it produced in series? That is no problem at all at Vidra Metaalbewerking BV Our production facilities are very flexible and scalable. We are happy to produce a test model for you. If the model meets your requirements and wishes, it can in principle be produced in any desired quantity. We store your design in our database, so that you can always have it produced again.

If you do not yet have a suitable design, our designers will be happy to assist you in realising a suitable design for your tube product.

The advantage of professionals

The team at Vidra Metaalbewerking BV consists of enthusiastic professionals who want to serve you as well as possible. Do you have questions about the best design for your tubes, or about the various options for production? We are happy to think along with you about the solution that best suits your own production processes. Vidra Metaalbewerking is the reliable and expert supplier for all your tube products.

Outsourcing work at Vidra

Step 2.

Upload your part with the requested information about, from, for, material, delivery date, quantities and any other specific wishes and requirements.

Step 3.

We will get to work to provide you with a quote quickly.

Step 4.

If the quotation meets your requirements and you agree, we will start producing your products to your complete satisfaction.