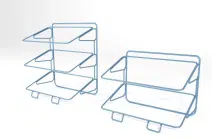

Versatile and flexible

In our factory in Nijverdal we have wire bending machines for all kinds of products (steel, stainless steel and aluminium): For the production of test models and small series we use hydraulic (manual) bending machines. Zero series and medium series are made with CNC bending machines.

For larger series, we have punching and bending machines, which are suitable for production from 10,000 pieces up to and including series of more than 100,000 pieces. You can therefore come to us for wire products in almost all shapes and in any desired quantity. We store the design of your product for possible additional production rounds.

Welding and finishing

Composite wire and tube constructions are welded by means of spot welding (resistance welding). If spot welding is not possible or does not suffice, we apply Mig/Mag or Tig welding.

Of course, we finish your wire products as you wish. For example, with an extremely hard and protective powder coating. Other surface treatments are also possible. We are happy to tell you more about the various possibilities.

Outsourcing work at Vidra

Step 2.

Upload your part with the requested information about, from, for, material, delivery date, quantities and any other specific wishes and requirements.

Step 3.

We will get to work to provide you with a quote quickly.

Step 4.

If the quotation meets your requirements and you agree, we will start producing your products to your complete satisfaction.